-

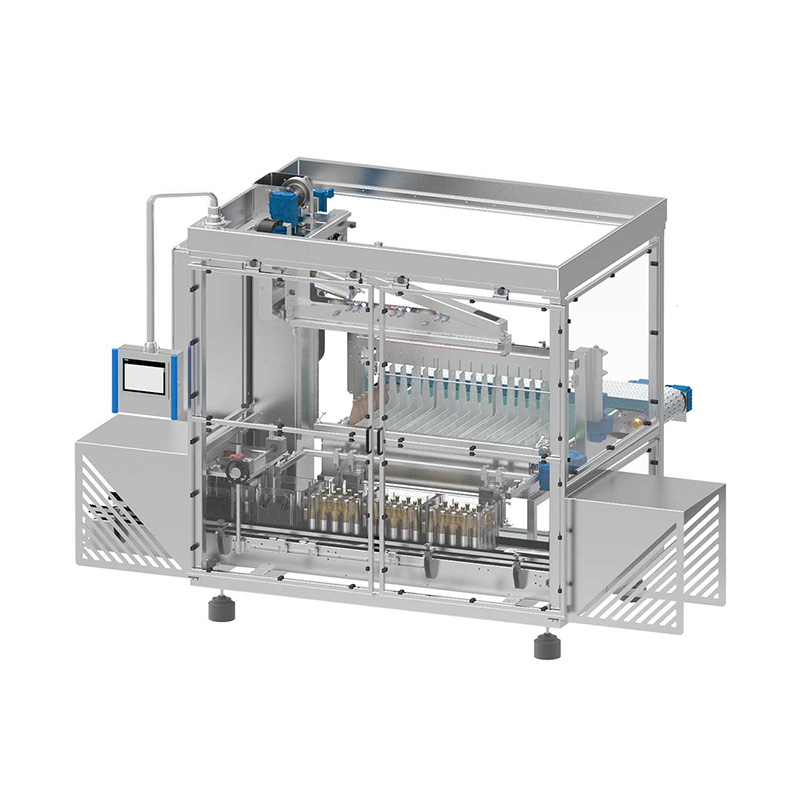

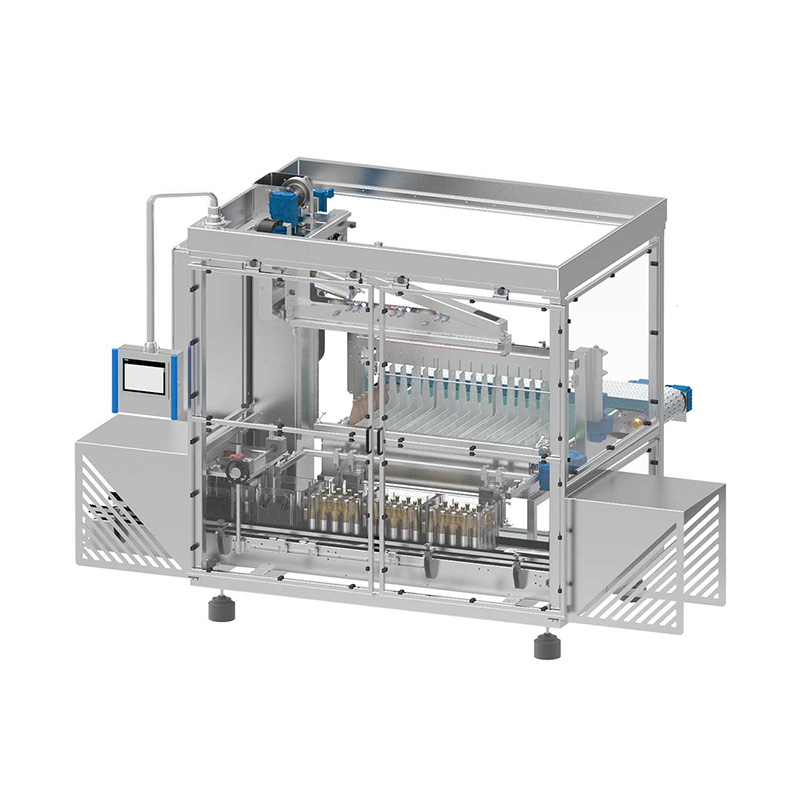

Automatic Bottled Drinking Water Filling Machine

Water and carbonated soft drinks are two of the most valuable beverage categories in the world. Our engineers know the liquid (water, beverage, liquor, etc.) packaging industry very well. We are proud to offer our customers a wide variety of bottled water equipment. We provide everything needed for the water filling and packing line. Whether you produce distilled water or soda water, we can help you achieve more with our solid expertise and strong packaging capabilities. Our filling equipment is manufactured in accordance with the strictest quality standards under guaranteed sanitary conditions, to provide customers with the best quality products, but also to provide customers with rich professional knowledge, production line equipment and continuous service. Ensures high quality and efficiency from packaging to equipment, ensuring that your products are stable and attractive to consumers.

-

Carbonated Soft Drink Filling Machine

Carbonated soft drinks (CSD) remain one of the most valuable beverage categories in the world, second only to bottled water in sales volume. Its world is colorful and sparkling; With consumer needs constantly changing, CSD production needs flexibility to achieve maximum volume in order to introduce new CSD products quickly and efficiently. Learn about our complete CSD solutions and how we can help you enhance your CSD production line for optimal performance and flexibility while reducing your production consumption costs.

-

Automatic Glass Bottle/ Plastic Bottle/ Can Hot Filling Juice Machine

While you strive to create unique, refined drinks for your customers, your bottling equipment should maintain the same level of precision and craftsmanship. JH-HF series filling machine is the best choice for PET& glass bottle hot filling steam free products. It can be used to fill juice, nectar, soft drinks, tea and other drinks. Sales of these drinks are growing fast, and they represent a healthier lifestyle driven by urbanization and improved retail infrastructure. No matter what kind of beverage you have, we can help you package your dreams through our technical expertise and superior packaging capabilities.

-

Automatic Glass Bottle/ Can Beer Filling Machine

Beer is one of the oldest alcoholic drinks in the world, and even now it is the most popular alcoholic drink in many countries, with various traditional activities associated with drinking beer. In recent years, the “high-end” craft beer began to appear more and more in the market and consumers. Unlike industrial beers, craft beers focus on taste and flavor, leading to a richer, fresher drinking experience. Craft beer has attracted the attention of many young people with its strong malt flavor and rich taste, and has gradually become popular.

-

The Linear Cans Filling Machine

As a supplement to the high-speed rotating can filling machine, the linear cans filling machine can also fill a wide variety of products such as: beer, carbonated/soft drinks, fruit juices, sports drinks and teas. Because of its small footprint, flexible filling products, quick and convenient can replacement, so it is more popular with small-scale users. For example, using a linear can to fill craft beer is a small machine, but it also has a variety of functions (storage tank, rinse, CO2 purge, filling, lid, sealing). These functions are no different from those of rotary filling machines. There is also a short cycle time from the beer filling, to hang the lid, roll sealing, which maximizes the oxygen increase in the beer filling process, to ensure that the beer is more fresh and not oxidized.

-

Rotating Can Filling Machine

Cans with its light weight, small size, easy to break, easy to carry and other advantages, favored by the majority of consumer groups. At the same time, it is made of metal material, so it has good protection from light. In contrast, glass bottles have poor anti-light performance. If glass bottles of drinks or beer are stored, they need to be put in a cool place to avoid direct sunlight, otherwise, the shelf life will be affected. These characteristics make cans completely superior to glass bottles in some packaging areas.

-

Automatic Plastic Bottle Blowing Machine for Beverage/ Oil

In addition to making drinks and water, you also need to make packaging containers. For water, beverage, easy to carry and meet the filling requirements of the best choice is PET bottle. In addition to providing solutions for filling various beverages, we also provide machines for producing PET bottles for water, beverages or milk, as well as solutions for packaging containers specialized for alcohol, oil or various chemical products.

-

Automatic Mineral / Pure Water Treatement Plants

Water is the source of life and the basic ingredient of all living things. With the growth of population and the development of economy, the demand and quality of water are becoming higher and higher. However, the degree of pollution is getting heavier and the area of pollution is getting larger and larger. It seriously affects our health, such as heavy metals, pesticides, waste water from chemical plants, the main way to solve these problems is to do water treatment. The purpose of water treatment is to improve the water quality, that is, to remove harmful substances in the water through technical means, and the treated water can meet the requirements of drinking water. This system is suitable for groundwater and ground water as raw water area. The water treated by filtration technology and adsorption technology can reach GB5479-2006 “Quality Standard for Drinking Water”, CJ94-2005 “Quality Standard for Drinking Water” or “Standard for Drinking Water” of the World Health Organization. Separation technology, and sterilization technology. For special water quality, such as sea water, seabed water, design the treatment process according to the actual water quality analysis report.

-

Drink Beverage Pre-process System

A good drink must have good nutrition, taste, flavor and color. In addition, we pay more attention to the hygiene and safety of beverage products. High quality raw materials, unique formula, advanced technology, but also need to support sophisticated equipment. Pretreatment usually involves hot water preparation, sugar dissolution, filtration, mixing, sterilization and, for some beverages, extraction, separation, homogenization and degassing. And of course the CIP system.

-

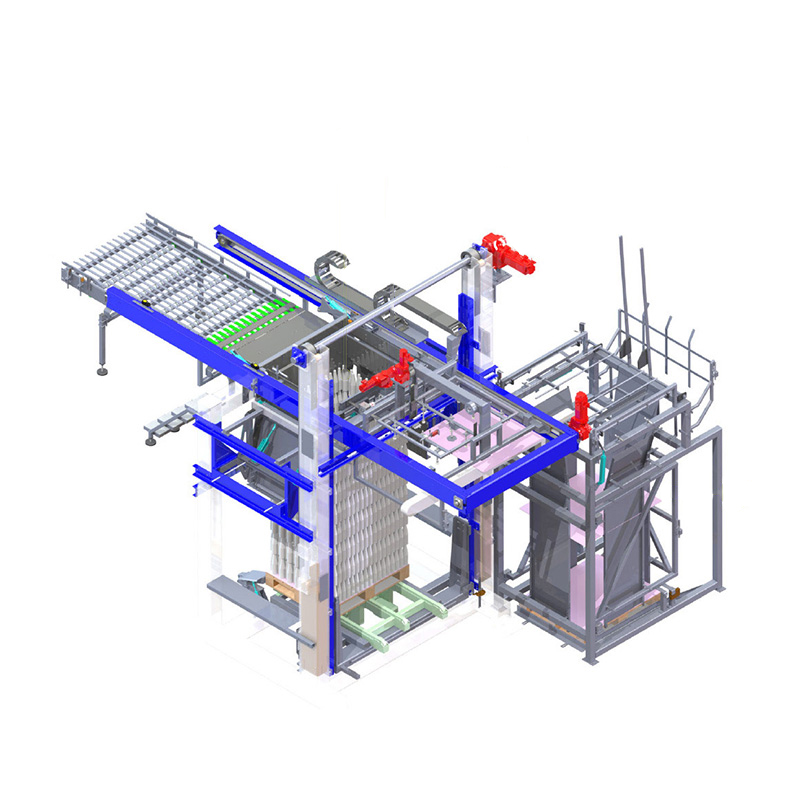

Automatic Bottle or Can Carton Box Packing Machine

The equipment is suitable for the automatic packing of bottled, box, canned, bag and other materials. The front end can cooperate with the unpacking machine to transport the empty carton completed on the back cover to the internal positioning of the packing machine; A single line of product feed, the equipment will automatically arrange the products, the special fixture will grab and transplant the products into the box, and the completed carton out of the equipment, the whole process is completed automatically, without manual intervention. Especially suitable for pipeline use, easy to move; PLC program control, simple operation, stable action.

-

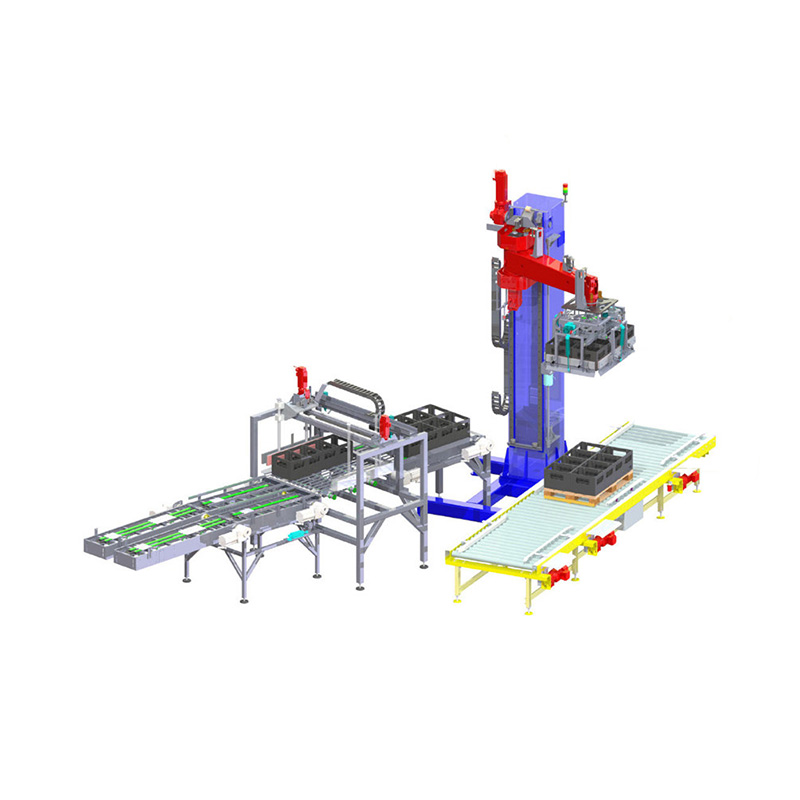

Automatic Galss Bottle/ Can Depalletizer Machine

Depalletizer machine is mainly used to unload the glass bottles (PET bottles, cans) to be unloaded to the bottle delivery chain, so as to carry out the whole line of production. This equipment belongs to the general equipment, can be widely used in beer, beverage, food, chemical, pharmaceutical and other industries of different bottle shape bottle unloading needs.

-

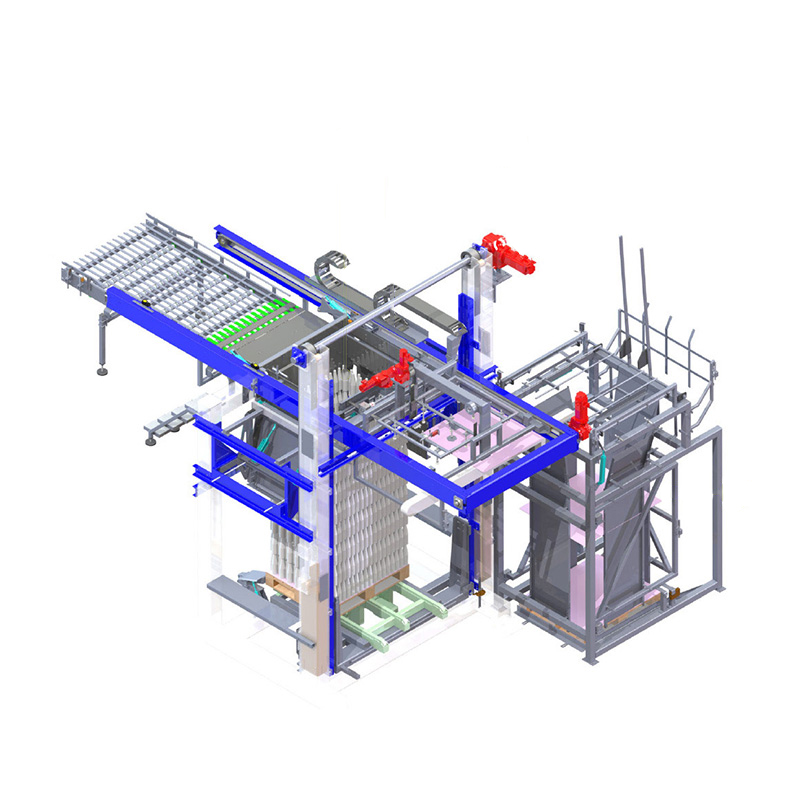

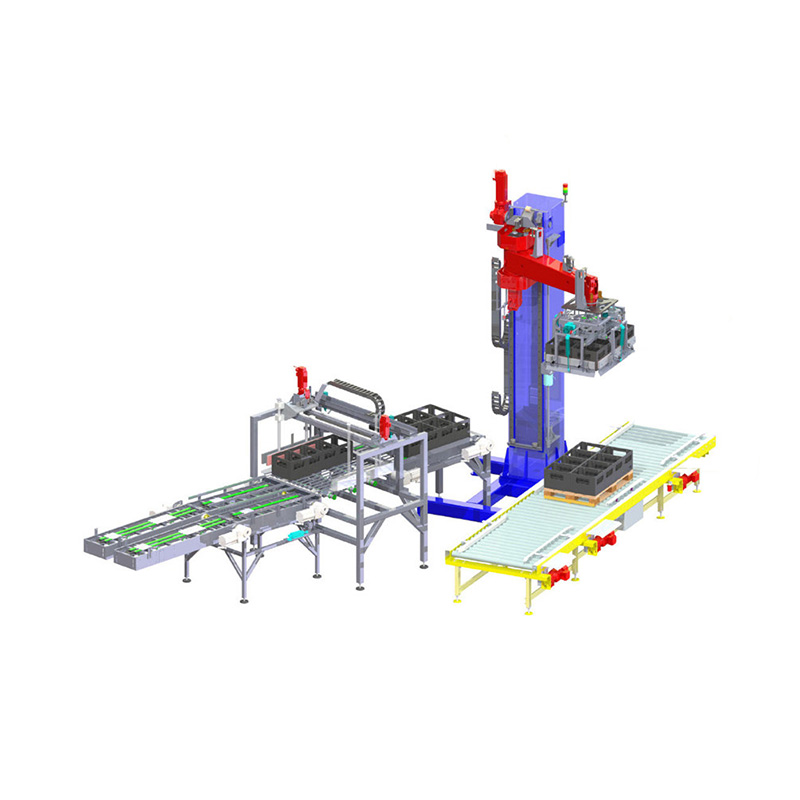

Automatic Robot Carton Box / Shrink Wrapping Palletizer

Robot palletizer is the product has been loaded into the carton, turnover box, bags and other rules of the product, through the conveyor line will be arranged and positioned; 10-12 neatly placed pallets are placed on the automatic pallet machine by forklift, and the machine automatically separates the pallets successively and sends them to the palleting position for positioning and palleting. The robot will grab the product through the special fixture, and in accordance with the pre-set placement on the pallet, the pallet conveyor line starts after the completion of the palletizing pallet output equipment, by the forklift fork to take off the line.