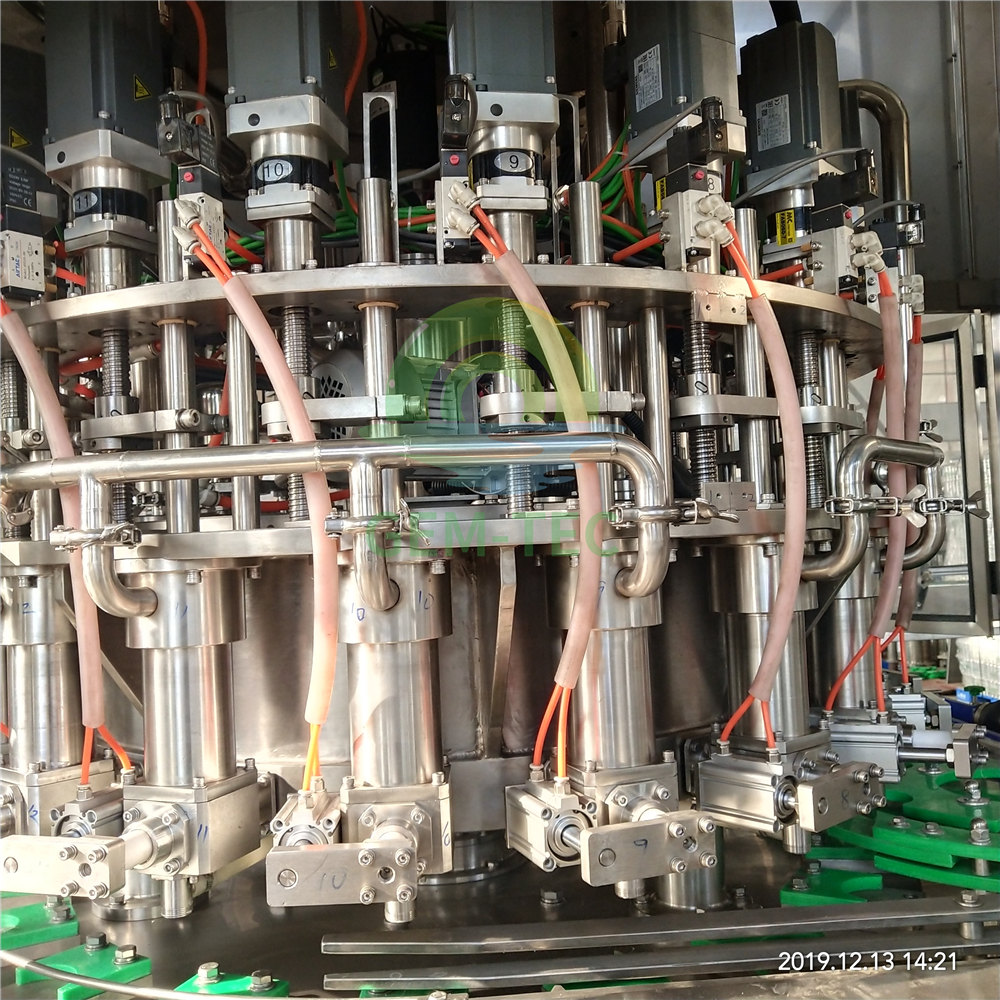

Rotating Can Filling Machine

Video

Description

Cans with its light weight, small size, easy to break, easy to carry and other advantages, favored by the majority of consumer groups. At the same time, it is made of metal material, so it has good protection from light. In contrast, glass bottles have poor anti-light performance. If glass bottles of drinks or beer are stored, they need to be put in a cool place to avoid direct sunlight, otherwise, the shelf life will be affected. These characteristics make cans completely superior to glass bottles in some packaging areas.

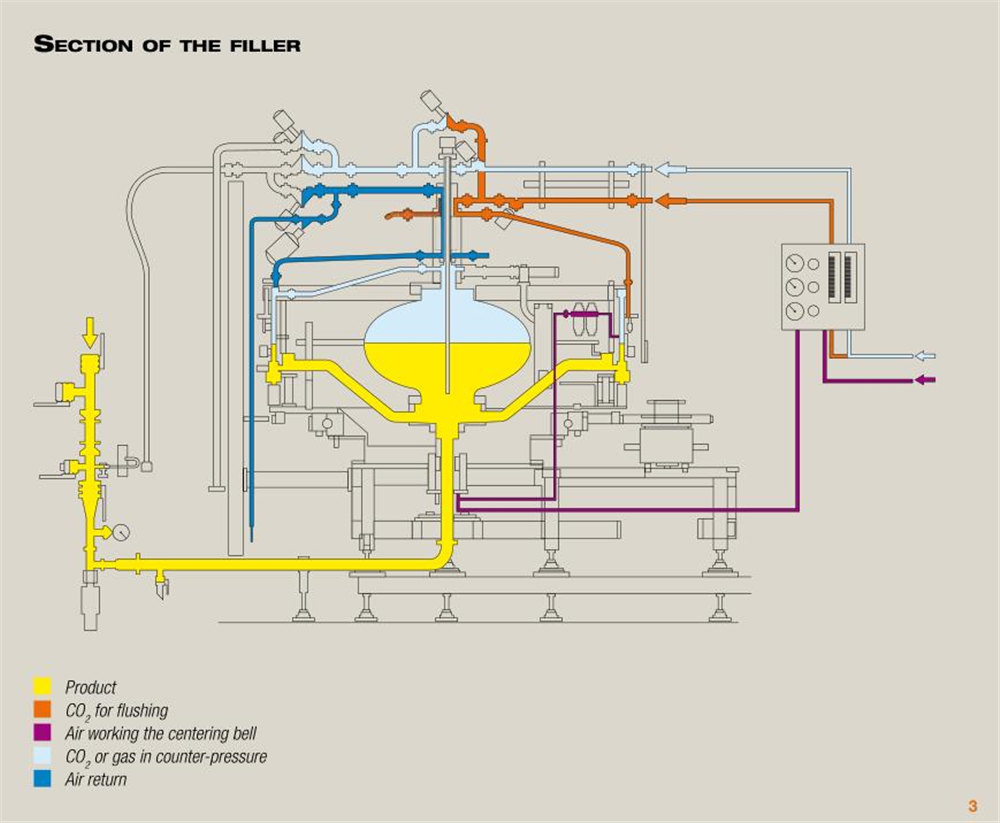

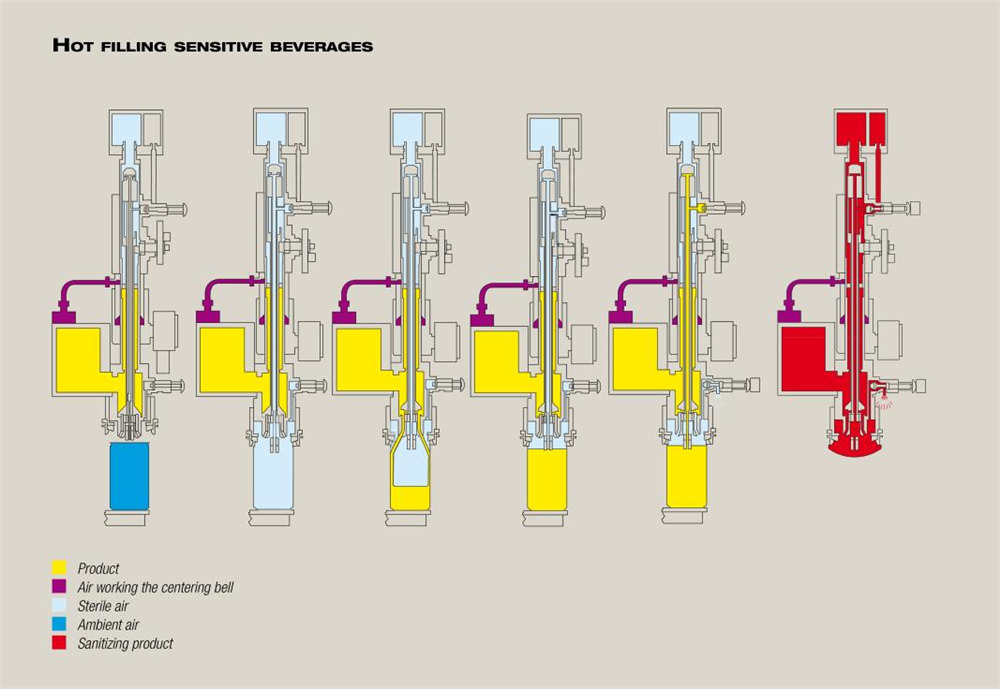

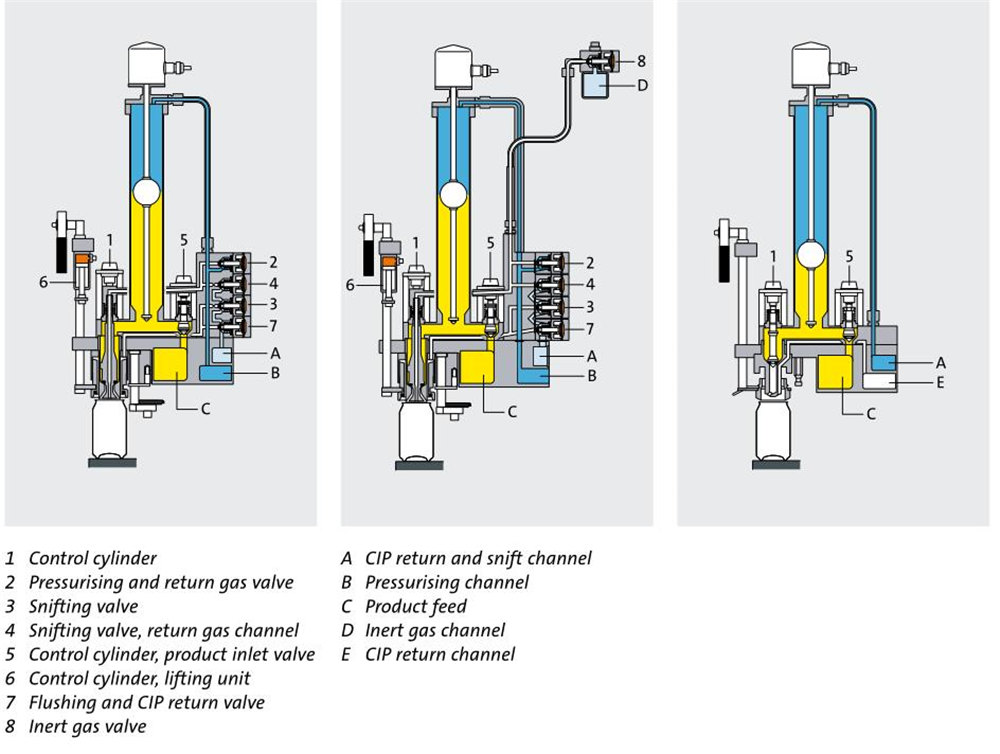

The GEM-TEC can filling machine has been developed with a wide variety of products in mind: beer, carbonated/soft drinks, fruit juices, sports drinks and teas to name a few. There is a suitable filling solution for each product. For example, in the hot filling mode required by juice and tea, it is equipped with a recirculation system to ensure that the product has a stable temperature, even during downtime. In the beer, CSD required by the isobaric filling method, equipped with CO2 displacement, CO2 purge, pressure, pressure relief and other functions; In the hydrogen-rich water filling method, the filling method of down-filling and down-reflux is equipped for the characteristics of low density of hydrogen and easy escape. No matter what kind of drink, which filling method, we can customize the industry leading can filling technology for you.

1. Conventional filling valve using reliable, simple mechanical filling valve, according to different product configuration of the corresponding filling valve. Electronic weighing high-precision filling valve or electromagnetic flowmeter quantitative filling valve are selected according to the product type. Electronic valve cylinder with Teflon bellows for controlling process gases. Some mechanical and all electronic valves with pneumatic control of the center sleeve, no lifting CAM, the filling process does not need to lift cans.

2. Siemens control system, with high automation control ability, all parts of the function of automatic operation, no operation after startup (For example: filling speed follows the whole line speed, liquid level detection, feed adjustment, lubrication system, etc.)

3. The machine transmission adopts modular design, frequency conversion stepless speed regulation, wide range of speed regulation. The drive is equipped with automatic lubricating grease device, which can supply oil to each lubricating point according to the need of timing and quantity, with sufficient lubrication, high efficiency, low noise and long service life. It can also cooperate with the coiling machine to use servo electrical separation drive, no complex mechanical transmission can easily sit the filling machine and coiling machine synchronization, more reliable transmission, simple maintenance.

4. The height of the material in the filling cylinder is detected by the electronic probe, and the PLC closed-loop PID control ensures stable liquid level and reliable filling.

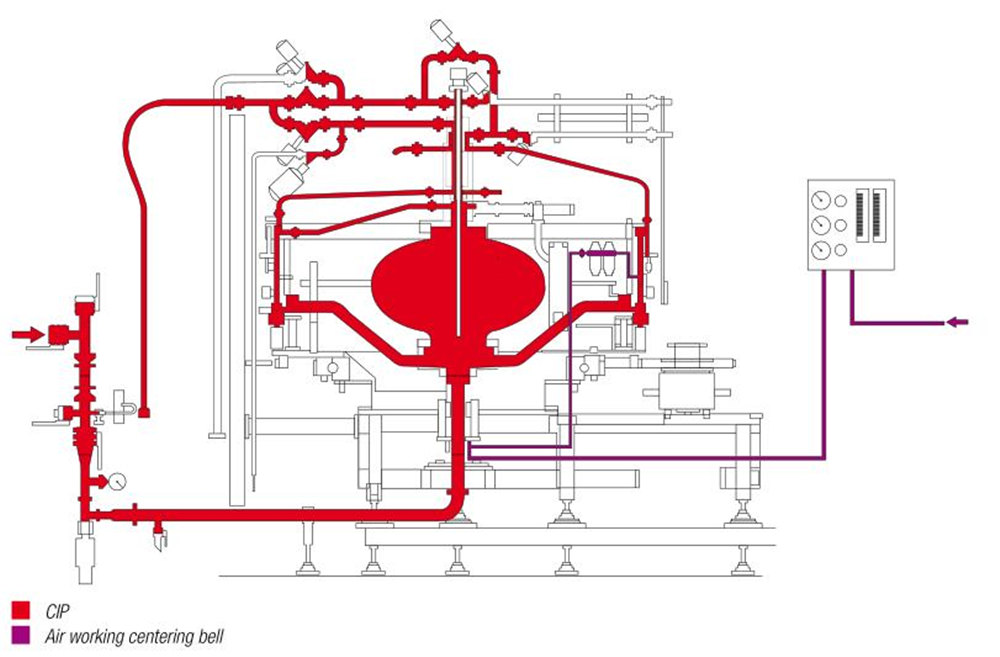

5. The material channel can be cleaned CIP completely, and the workbench and the contact part of the bottle can be washed directly, which meets the sanitary requirements of filling; Can be used according to the need of single-sided tilt table; Custom automatic CIP fake cups are also available.

6. Suitable for various brands and models of sealing machine.

In order to ensure the excellent taste and freshness of the drinks to be filled, it is necessary to roll and seal the can lid immediately after filling. Our high speed automatic can sealing machine is used to connect the various filling machines behind the canned food and beverage production line. The working principle is that the lower supporting tank seat drives the tank body to rotate and lift, and then the first and second sealing wheel act on the edge of the rolling head successively, and then through the sealing CAM to complete the sealing action. It can be configured with 2/4/6/8 coiling heads, with precise high-speed coiling capacity up to 700-800 cans per minute. Each model is equipped with multiple safety protection devices to ensure the second rewinding performance in high speed operation. Tank type replacement is extremely simple and fast.

Mechanical Characteristics

1. Modular structure is compact, spindle and all parts of the bearing with central automatic oil supply lubrication, built-in coil sealing wheel lubrication.

2. Controlled by frequency converter, the production speed can be adjusted freely; The servo motor technology can be selected to realize the separation and synchronous transmission of the perfusion machine and the coiling machine to reduce the mechanical transmission parts.

3. Coil sealing roller seat is easy to adjust, coil sealing roller using titanium nitride (TIN) surface coating treatment.

4. The standard tank cover decompression device (clamp cap), can reduce the tank cover feeding groove accumulation pressure.

5. The machine is equipped with multiple interlocking safety devices to ensure man-machine safety.

6. The contact surface between the transfer star wheel and the tank body is treated with chromium plating to prevent the tank body from being scratched.

7. HMI(touch screen) control, can reality machine state, failure type and complete production information.

8. Stainless steel body outer shield and toughened glass window.

9. Perfect sanitary design, easy to clean.

10. (Optional) Electric coil head lifting device.

11. (Optional) CO2 and vapor purging device under tank cover.

Parameter

| Technical parameter :beverage drink can filler machinery | |||||

| Model | JH-CF12-1 | JH-CF18-4 | JH-CF24-4 | JH-CF30-6 | JH-CF40-8 |

| Capacity(cans/hour) | 2000 | 8000 | 12000 | 15000 | 20000 |

| Suitable container | Aluminum Can / Tin Can / Plastic Can | ||||

| Can diameter | Dia50 ~ dia99mm | ||||

| Can height (mm) | 70-133mm | ||||

| Compressor air | Isobaric filling / normal pressure filling | ||||

| Application | Beverage Can Filling Machine | ||||

| Total power (kw) | 2.4kw | 4.4kw | 5.2kw | 6.2kw | 7.2kw |

| Overall dimensions | 2.5*1.9m | 2.8*1.9m | 3.2*2.15m | 3.5*2.5m | 3.8*2.8m |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m |

| Weight(kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg |

Structure