Automatic Glass Bottle/ Plastic Bottle/ Can Hot Filling Juice Machine

Description

While you strive to create unique, refined drinks for your customers, your bottling equipment should maintain the same level of precision and craftsmanship. JH-HF series filling machine is the best choice for PET& glass bottle hot filling steam free products. It can be used to fill juice, nectar, soft drinks, tea and other drinks. Sales of these drinks are growing fast, and they represent a healthier lifestyle driven by urbanization and improved retail infrastructure. No matter what kind of beverage you have, we can help you package your dreams through our technical expertise and superior packaging capabilities.

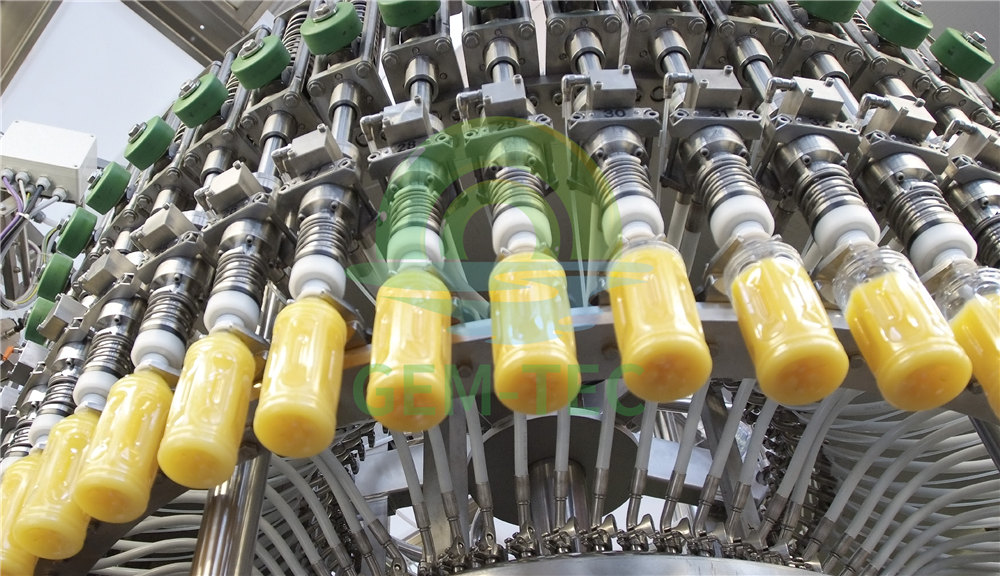

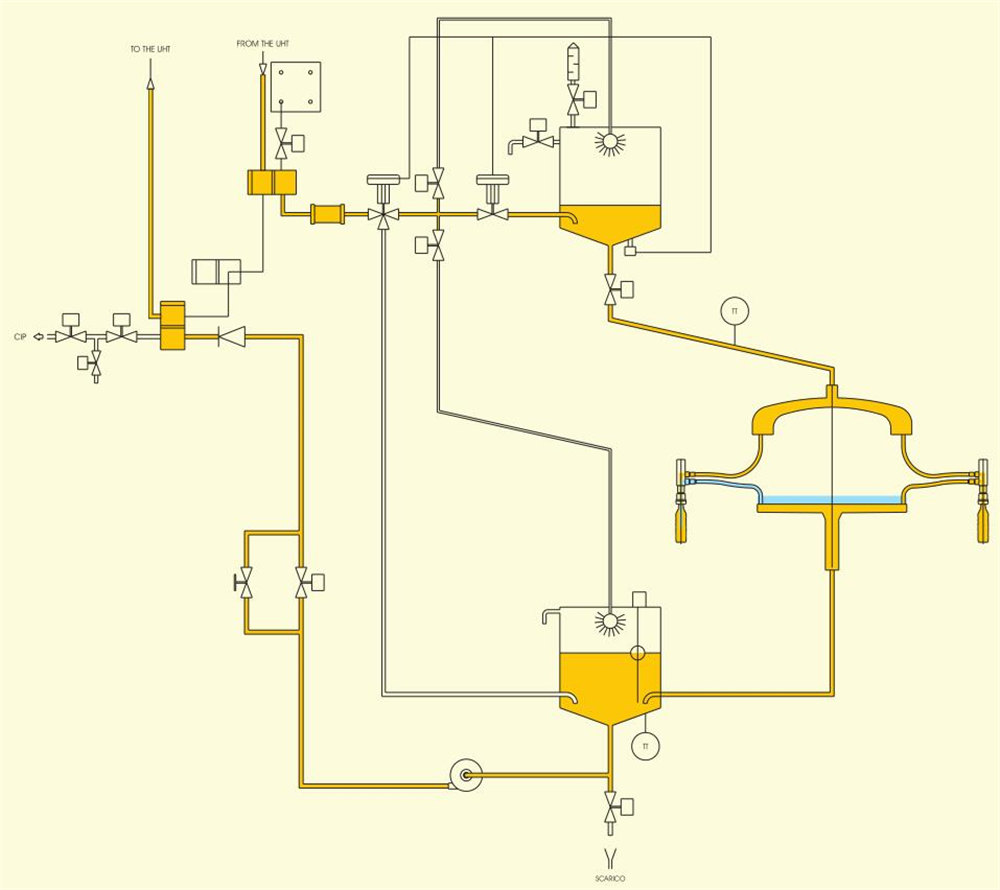

Hot filling technology represents a solution for filling static beverages without the addition of preservatives such as fruit pulp or fiber. Hot products at high temperatures (up to 92-95°C, depending on product specifications) are kept in a high temperature and sterilized state from the pasteurizer to the filling machine to ensure the desired shelf life. The thermal filling system is equipped with a recirculation function to ensure that the product is sterile at all times. When the machine stops running, product recirculation starts, keeping the filling valve temperature constant. Recirculation is only for products located in the filling valve, not for bottled products. During filling, the filling valve moves in contact with the bottle. The bottle in contact with the valve opens the valve without product recirculation. The air from the bottle is discharged through the product recirculation tube. Once the filling level is reached, the product recirculation begins again. Then the pneumatic valve closes the filling head and stops the product recirculation. Once filled and capped, the bottle goes into a cold-shower tunnel for cooling.

In order to maximize the protection of the product from bacterial contamination and to maximize the cleaning efficiency of the equipment, the product is distributed through the pipe to the rotating dispenser. The upper end of the distributor is connected with the material storage tank, the storage tank can accept the material from the sterilization machine and can return the circulating material in the filling valve to the sterilization machine to continue sterilization. The tank section is cleaned with a spray ball. The delivery and return of the product within the filling valve is also designed to minimize product loss at the beginning and end of production. This special filling valve does not require the installation of a false cup for CIP cleaning because there is a closed loop within the valve that allows cleaning to be performed. The shape of the contact area between the fixed and moving parts is designed to provide an appropriate cleaning flow rate.

Features

Hot fill technology features

1. The equipment has an external tank for feeding and recycling products. When the machine has no bottles, the product is recycled: the filling head is always kept at high temperature.

2. Siemens control system, with high automation control ability, all parts of the function of automatic operation, no operation after startup.

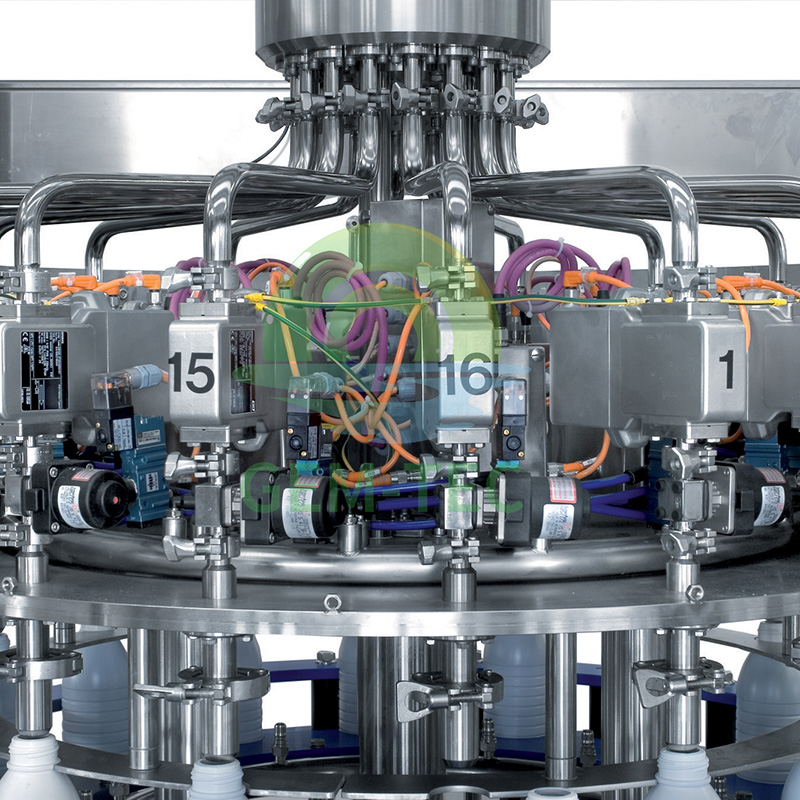

3. Electronic and pneumatic control of all filling valves, easy maintenance. Optional precise quantitative filling, induction type electromagnetic flowmeter volumetric filling, filling valve and bottle do not contact during the filling process, avoid cross contamination.

4. The material channel can be cleaned CIP completely, and the workbench and the contact part of the bottle can be washed directly, which meets the sanitary requirements of filling; Custom automatic CIP fake cups are also available.

5. To ensure the highest level of hygiene at each step, the machine is constructed of stainless steel and has a sloping countertop to reduce the risk of microbial contamination.

6. Advanced recirculation control with external actuator in pneumatic version of membrane valve to control product recirculation rate and avoid product spatter.

7. The machine transmission adopts modular design, frequency conversion stepless speed regulation, wide range of speed regulation. The drive is equipped with automatic lubricating grease device, which can supply oil to each lubricating point according to the need of timing and quantity, with sufficient lubrication, high efficiency, low noise and long service life.

8. Different versions can be provided according to customers' specifications.

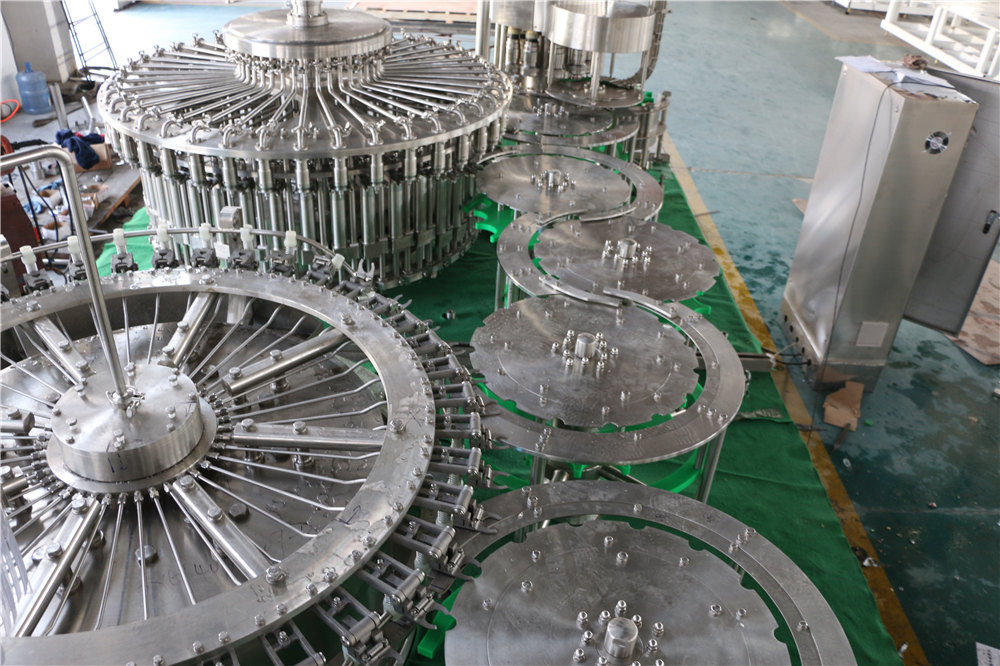

Structure

Technical Specfication

Partial Products Main Technical Parameter

| Model | Washing heads |

Filling heads |

Capping heads |

Production Capacity |

Machine Power |

Weight | Overall dimension (mm) |

| JG-HF 14-12-4 | 14 | 12 | 5 | 4000B/H (500ml) | 3kw | 3200kg | 2500*1880*2300mm |

| JG-HF 18-18-6 | 18 | 18 | 6 | 8000B/H (500ml) | 3kw | 4500kg | 2800*2150*2300mm |

| JG-HF 24-24-8 | 24 | 24 | 8 | 8000B/H (500ml) | 5kw | 6500kg | 3100*2450*2300mm |

| JG-HF 32-32-10 | 32 | 32 | 10 | 15000B/H (500ml) | 6kw | 7500kg | 3680*2800*2500mm |

| JG-HF 50-50-12 | 50 | 50 | 12 | 20000B/H (500ml) | 11kw | 13000kg | 5200*3700*2900 mm |