Carbonated Soft Drink Filling Machine

Video

Description

Carbonated soft drinks (CSD) remain one of the most valuable beverage categories in the world, second only to bottled water in sales volume. Its world is colorful and sparkling; With consumer needs constantly changing, CSD production needs flexibility to achieve maximum volume in order to introduce new CSD products quickly and efficiently. Learn about our complete CSD solutions and how we can help you enhance your CSD production line for optimal performance and flexibility while reducing your production consumption costs.

JH-YF carbonated soft drink filling machine is suitable for all kinds of PET/ glass carbonated soft drink. Reliable isobaric (counter-pressure) filling technology is adopted. Our filling technology can help high-end brands increase bottling production in an economical and fast way. Reduce co2 consumption, reduce beverage consumption rate.

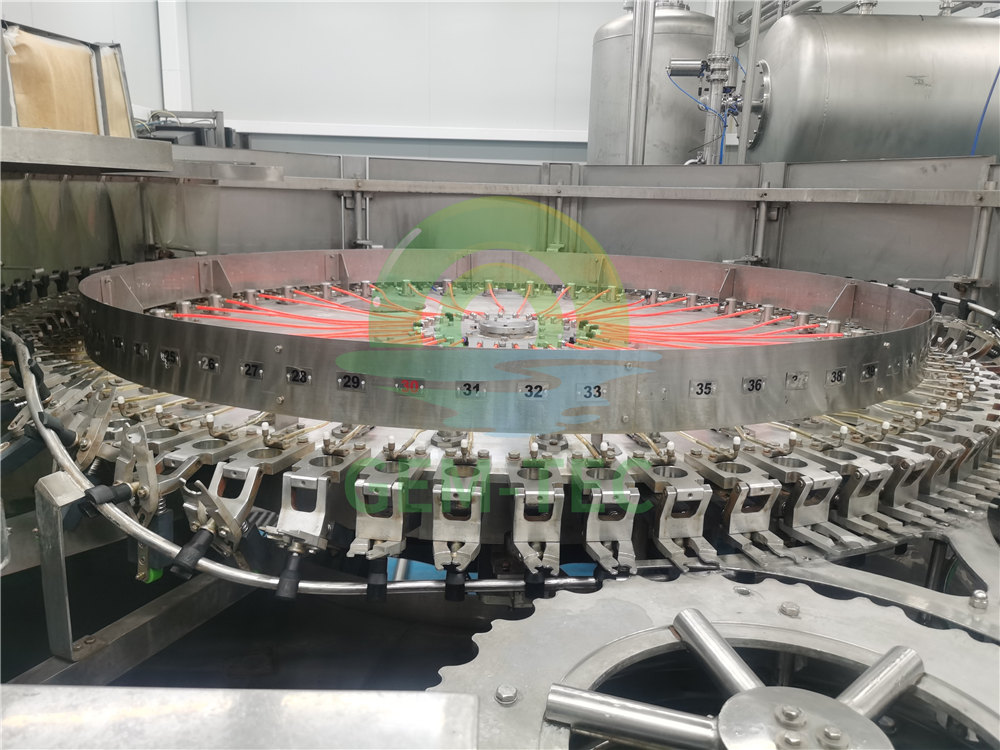

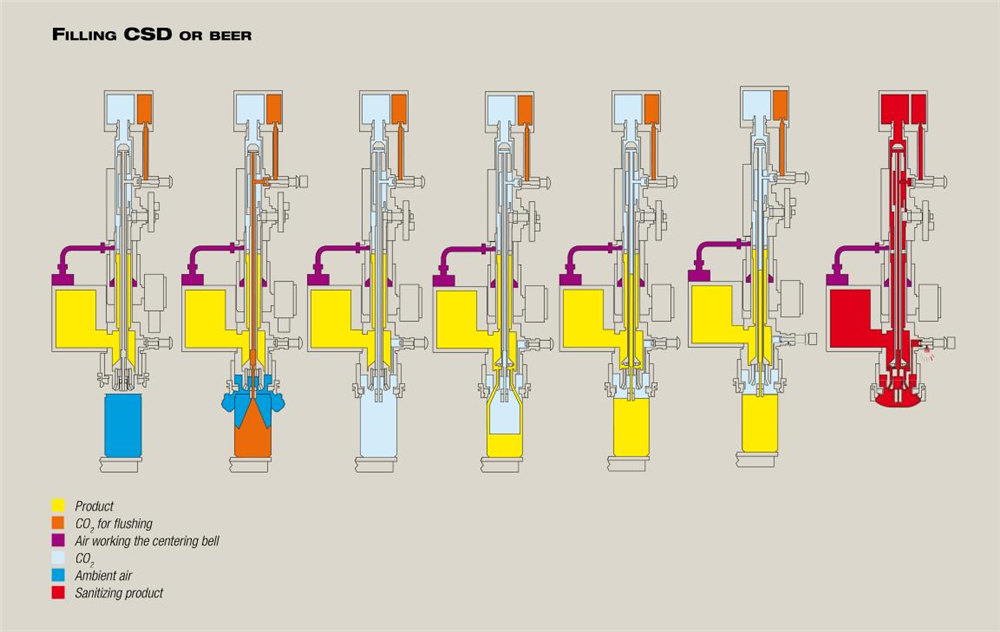

Conventional models use stable and easy to clean mechanical filling valves, including open and close valves, CO2 purge, CO2 inflation, post-filling pressure relief are all controlled by mechanical cams.

Filling Operation Method

Start by pressing the mouth of the PET/ glass container firmly and pressurizing the inside of the bottle. When the spare pressure of the cylinder and the pressure inside the bottle are the same, the spring will open the valve and the filling process will begin immediately; The filling continues until the liquid level reaches the lower end of the return pipe, and the filling is stopped. After a settling stage, the valve closes; When the pressure of the bottleneck is removed, the filling is finished.

Technical Structure Features

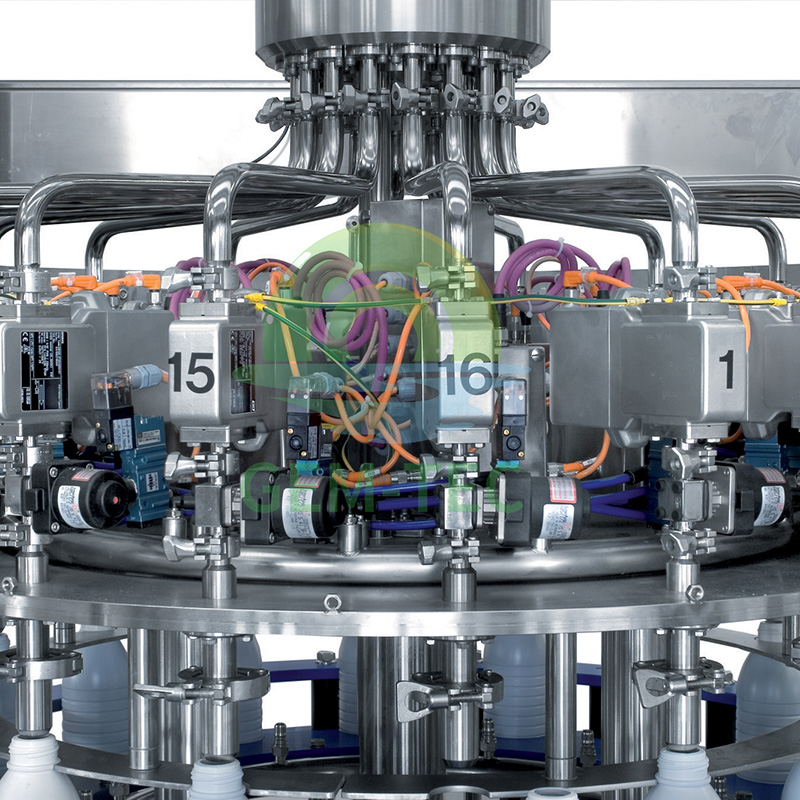

1. Filling valve adopts high precision mechanical filling valve. (Optional electronic valve Level valve/electronic volume valve)

2. In the flushing or filling, due to the bottle quality problems caused by the bottle burst, the filling valve is automatically closed, and there is a broken bottle automatic flushing device.

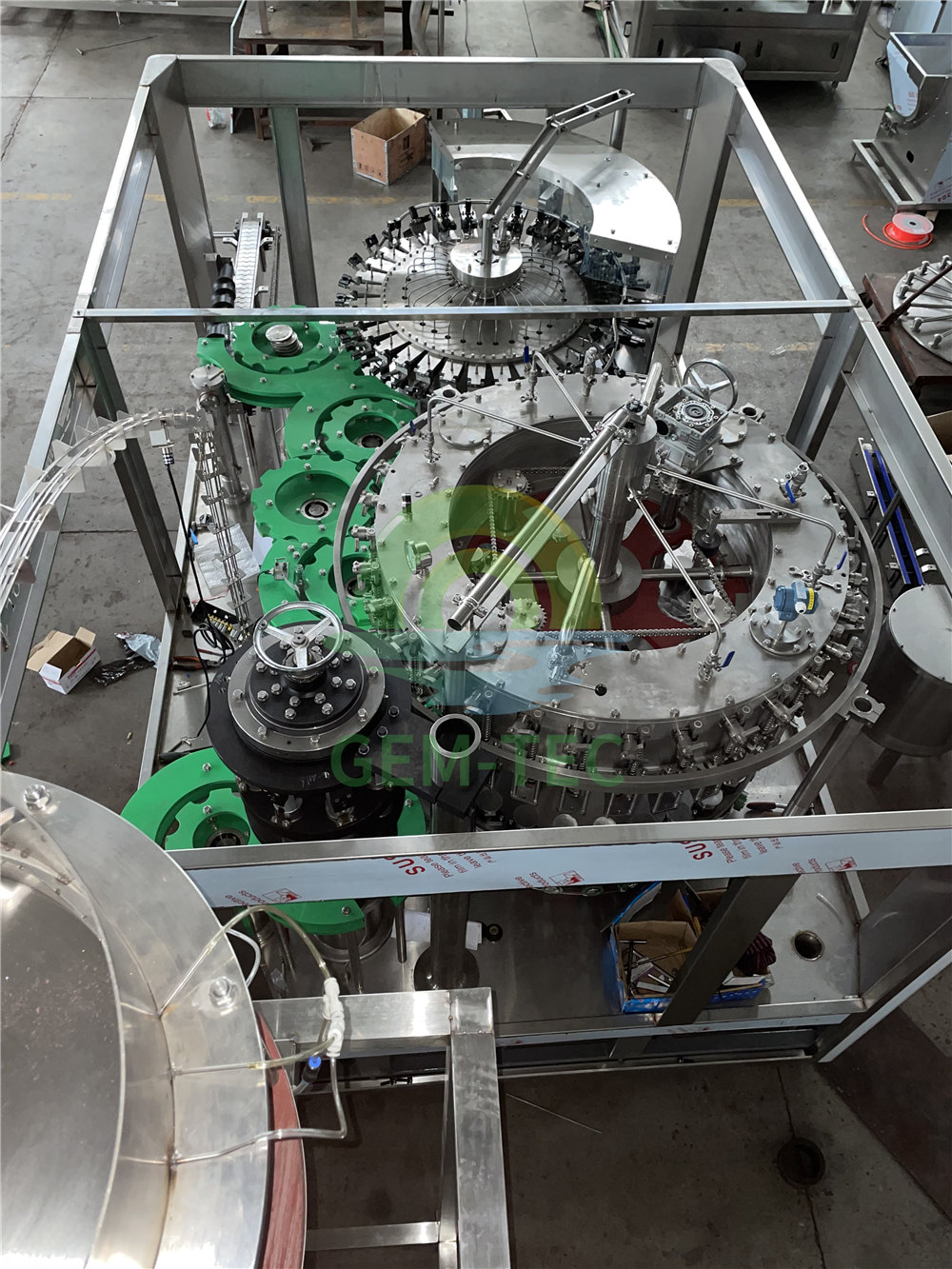

3. The machine transmission adopts modular design, frequency conversion stepless speed regulation, wide range of speed regulation. The drive is equipped with automatic lubricating grease device, which can supply oil to each lubricating point according to the need of timing and quantity, with sufficient lubrication, high efficiency, low noise and long service life.

4. The back pressure of the material in the filling cylinder can be automatically controlled, and its working conditions and parameters can be displayed on the control cabinet.

5. The height of the material in the filling cylinder is detected by the electronic probe. PLC closed-loop PID control ensures stable liquid level and reliable filling.

6. The height of the filling cylinder and control ring can be adjusted to suit the filling of containers of different sizes within the design range.

7. The use of all stainless steel cover hopper, the cover of the cover, the cover, into the cover transmission is reliable, in the operation of the cover is not easy to deformation, the cover is large and unobstructed,

8. The gland is reliable; And has automatic unloading function, reduce the broken bottle rate.

9. Siemens control system, with high automation control ability, all parts of the function of automatic operation, no operation after starting (such as: filling speed follow the whole line speed, liquid level detection, liquid inlet regulation, bubble pressure, lubrication system, cover conveying system)

10. The material channel can be cleaned CIP completely, and the workbench and the contact part of the bottle can be washed directly, which meets the sanitary requirements of filling; Can be used according to the need of single-sided tilt table;

11. A variety of sealing methods (such as: crown cover, pull ring cover, metal or plastic anti-theft cover, etc.)

According to the requirements of different users and different products, filling valve can also use electronic filling. This filling method controls the opening and closing of the beer valve, vacuuming, exhaust pressure relief and other actions are pneumatic control, and the filling flow rate can be adjusted appropriately. The structure is more simple, reliable and easy to maintain. You can also customize the fully automatic CIP function, cleaning fake cups automatically mount, no manual operation is required. For customers who require accurate filling volume, electronic quantitative filling valve can be used to change the capacity. As long as the filling speed is adjusted on the HMI, accurate switching can be achieved.

Technical Specfication

| type | Production capacity (BPH) | Pitch circle diameter | size | |

| JH-PF14-12-5 | 1500-2000/(500ml) | Φ600 | ||

| JH-PF24-18-6 | 2500-3500 | Φ720 | ||

| JH-PF32-24-8 | 3500-4500 | Φ960 | ||

| JH-PF40-32-10 | 7000-8000 | Φ1120 | ||

| JH-PF50-40-12 | 10000-12000 | Φ1400 | ||

| JH-PF60-50-15 | 13000-16000 | Φ1500 |